White Paper: Smarter, Safer Pipe Handling

A comparison between PIPEBOSS and traditional methods—highlighting ROI, safety, and efficiency.

The Pipelaying Industry: Hazards of Using Slings and Chains to Move Pipes and Recent Injury Trends

Uncovering 5 Years of Injury Trends in the Pipelaying Industry

The pipelaying industry is a critical sector in infrastructure development, responsible for installing pipelines for water, oil, gas, and other utilities. One of the most common methods of moving heavy pipes involves using slings and chains, which, while effective, pose significant safety risks. Over the past five years, numerous injuries and accidents have been reported due to equipment failure, improper handling, and inadequate safety measures. This article explores the hazards associated with slings and chains in pipelaying, examines injury trends from 2019 to 2024, and highlights innovative solutions like PipeBoss that enhance workplace safety.

Uncovering 5 Years of Injury Trends in the Pipelaying Industry

The pipelaying industry is a critical sector in infrastructure development, responsible for installing pipelines for water, oil, gas, and other utilities. One of the most common methods of moving heavy pipes involves using slings and chains, which, while effective, pose significant safety risks. Over the past five years, numerous injuries and accidents have been reported due to equipment failure, improper handling, and inadequate safety measures. This article explores the hazards associated with slings and chains in pipelaying, examines injury trends from 2019 to 2024, and highlights innovative solutions like PipeBoss that enhance workplace safety.

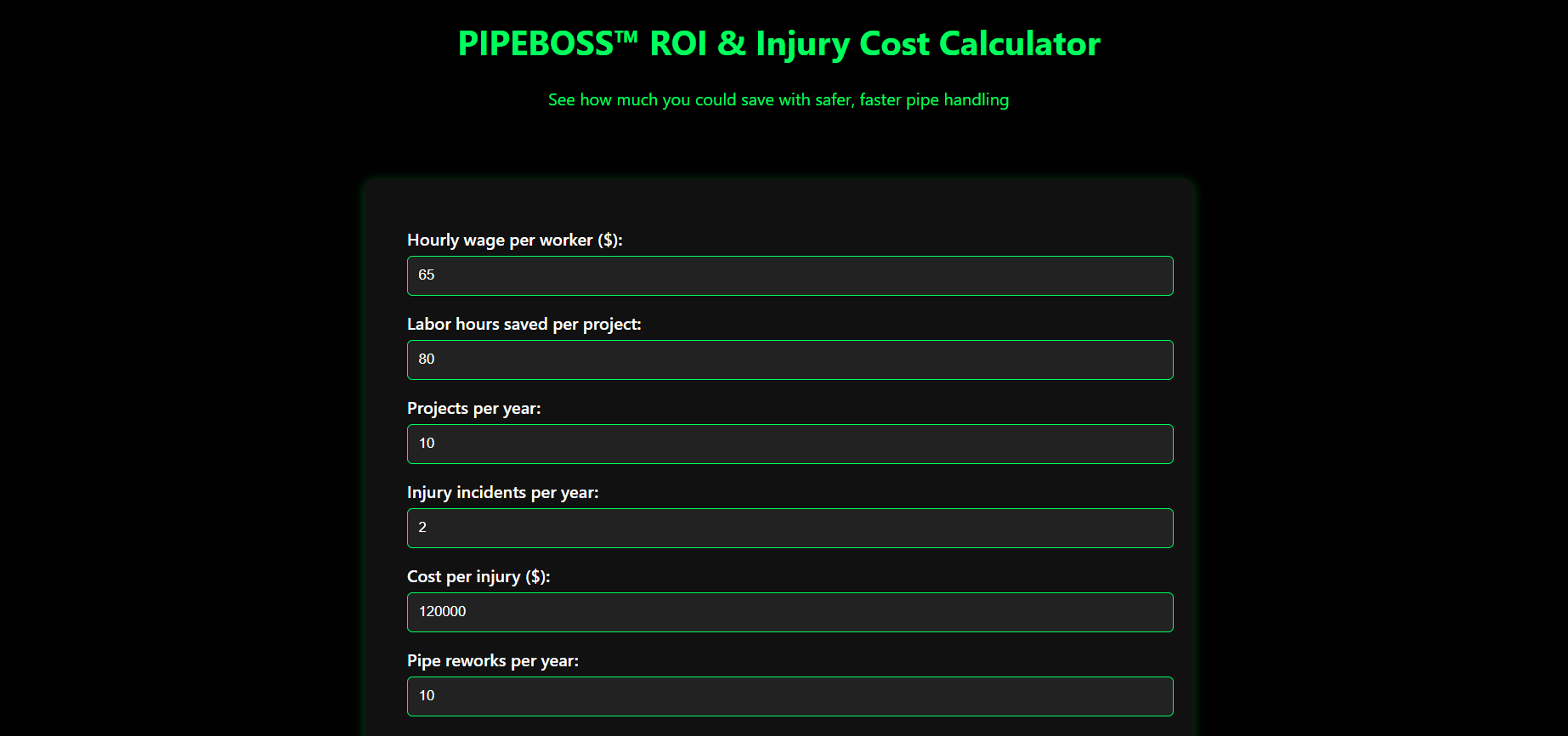

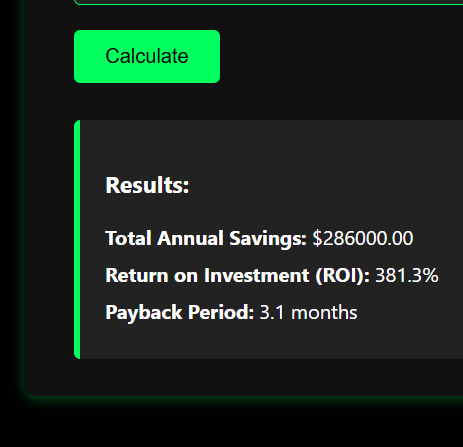

Calculate Your Project Savings

Estimate savings on labour, time, and insurance risk.

Built for Tier 1 Safety, Backed by Standards

PIPEBOSS isn’t just a tool — it’s a strategic response to the rising demands of compliance, accountability, and workplace safety. Designed for high-risk environments and trusted by Tier 1 operators, PIPEBOSS sets a new benchmark in compliant pipe handling.

Reduces Legal & Insurance Risk

Lowers injury liability

Improves Tier 1 contract prequalification

Strengthens audit results

Certified

Safety

ISO 45001 Compliant

WHS Ready

Covers key safety mandates

Engineered to

Eliminate Risk

No manual pipe handling

Avoids trench entry

Remote-controlled operation

Delivers Commercial Confidence

fewer delays

Happier teams

Safety built-in, not added on

Machine Specifications

1400(max)

Max Pipe Dia 880 Dia/525mm

Collapsed length 1868mm

Extended length 2500mm

Battery 12 Volt

Weight 17kgs

Total shipping weight

570kgs

Maximum pipe size NB 750 (925mm)

Hitch pin diameter 80mm Dia (standard fit custom available on request)

Hitch pin PCD 460mm (standard fit custom available on request)

Hydraulic operating pressure—restricted internally

Battery 12Volt

Maximum lifting capacity 3000Kgs

Articles & Insights

Learn & Compare.